Project Introduction

My team was tasked with designing and manufacturing a compliant end-effector for an actuated robotic arm to pick up an egg without external force modulation—and move it without dropping or cracking it.

Problem Statement

- The end-effector must affix securely to the arm.

- Generate between 6–10 N of force.

- Hold the egg without breaking or dropping it.

Proposed Solution

- Introduce bending compliance because the arm cannot regulate force output precisely.

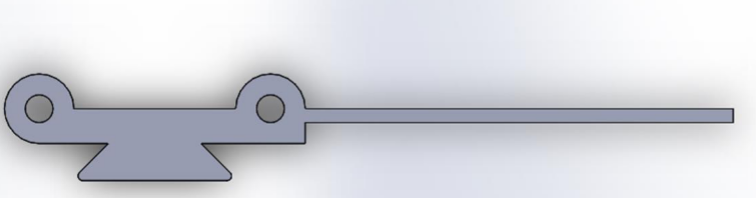

- Use a cantilever beam to multiply force through leverage and generate a gripping moment.

Implementation

- Use a thicker root section for the cantilever to handle peak load.

- Taper the distal region to reduce stiffness and improve conformity.

- Mount via a dovetail rail for alignment and quick swapping.

Finite Element Analysis

- Iteratively narrow the beam to maximize performance while maintaining safety factors.

- Remove low-stress material to reduce weight and improve compliance.

- Fillet edges to minimize stress concentrations at transitions.